An SPD (Surge Protective Device) contains at least one nonlinear component. When a surge occurs, the SPD can conduct within an extremely short time, discharging the current to the ground. Its response time is in the nanosecond range (10-9 seconds), while the surge's rise time is generally in the microsecond range (10-6 seconds). Thus, an SPD can limit the voltage to a safe level, protecting the equipment.

An SPD can be understood as an "instantaneous grounding device." For non-live objects such as equipment casings or pipes, direct grounding is generally possible. For live circuits, instantaneous grounding is achieved through the SPD.

Common nonlinear components inside an SPD include TVS (Transient Voltage Suppression Diode), MOV (Metal Oxide Varistor), and GDT (Gas Discharge Tube).

Among these components, TVS responds the fastest but has a smaller discharge current capacity. GDT has a large discharge capacity but responds more slowly. MOV has moderate discharge capacity and response speed.

There are many types of SPDs. From an application perspective, SPDs can be divided into power SPDs and signal network SPDs. The main differences are:

The power circuit operates at a high current, while the signal network circuit operates at a lower current.

Power SPDs require a larger discharge current, while signal network circuits require a smaller discharge current.

In practical applications, power SPDs are usually installed in parallel, using MOV for single-stage protection.

Parallel installation is used because the power circuit operates at a high current. If installed in series, the SPD would need to withstand a large loop current. MOV is used because TVS lacks discharge capacity and GDT has power frequency follow current issues. Single-stage protection (with a certain distance between different stages) is used to meet energy coordination requirements.

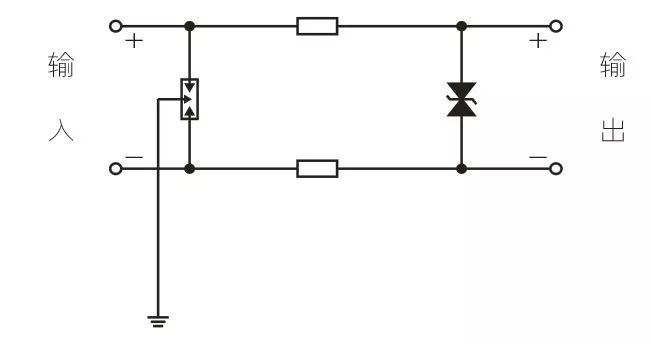

Signal surge protection device are generally installed in series, using GDT and TVS for two-stage protection. SPDs can be installed in series.

Series installation is used because the signal circuit current is small, and it allows for multi-stage protection while meeting energy coordination. GDT (and TVS) is used instead of MOV because MOV has higher junction capacitance and, for the same discharge capacity, is much larger than GDT. Additionally, in signal circuits with small currents (voltages), there is generally no concern about power frequency follow current when using GDT.

Energy coordination means that when multiple SPDs or protective components with varying discharge capacities are used together, the lightning current must be reasonably distributed to ensure that SPDs or components with smaller discharge capacities are not damaged.

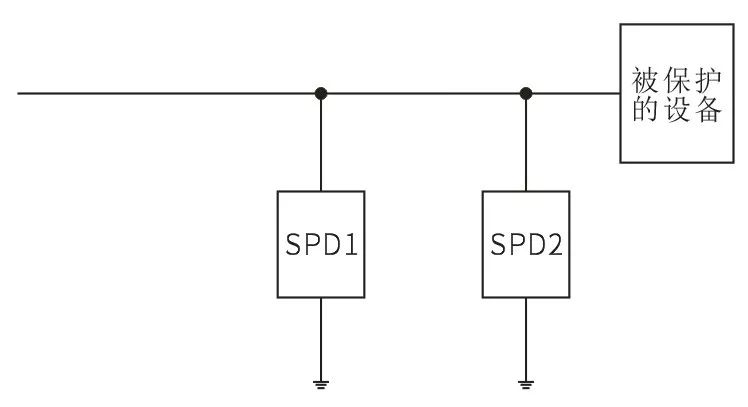

As shown in the figure, SPD1 has a large discharge capacity and high residual voltage, while SPD2 has a small discharge capacity and low residual voltage. To achieve better protection (large discharge capacity and low residual voltage), both SPD1 and SPD2 are used together. However, in practice, the lightning current may not distribute as expected, with a significant portion going through SPD1 and a smaller portion through SPD2. Without proper energy coordination, SPD2 might be damaged due to an excessive share of the lightning current.

The same energy coordination issue applies to signal surge protection device. Without proper coordination, TVS could be easily damaged.

For power SPDs, a spacing of 5-10 meters between stages during installation is required to achieve energy coordination. For signal surge protection device, a coupling resistor is generally added between GDT and TVS to achieve energy coordination. Since resistors consume power, they are only suitable for low-current signal circuits.