Intrinsic safety barriers and isolators use intrinsically safe explosion-proof and functional safety technologies and adopts various measures such as rapid cut-off, isolation, and energy limiting to ensure that the energy transmitted to the field equipment in the hazardous area is intrinsically safe, thereby preventing dangerous energy from entering the danger zone and causing an explosion.

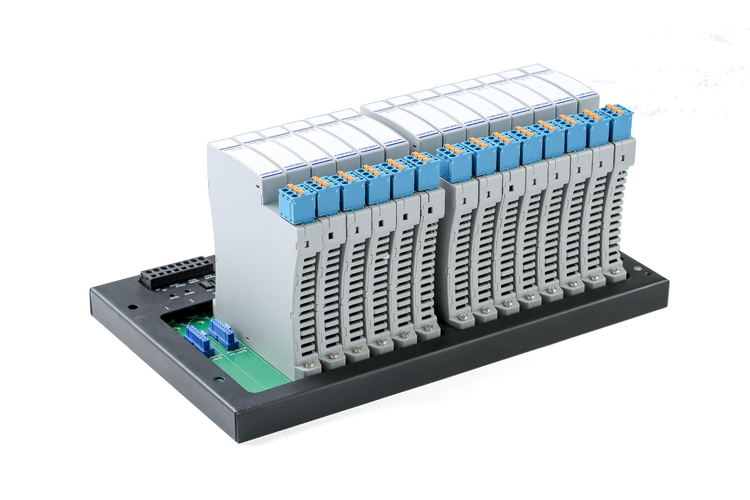

An isolated barrier, such as the digital input barrier, is a key interface unit in the intrinsically safe explosion-proof control system. The intrinsically safe barrier or the intrinsic safety barrier with quite affordable price made by CHENZHU, one of the top intrinsic safety barrier manufacturers in China, is made under a strict production process and tested by a series of quality assurance systems.

The isolator is used to adjust, isolate and transform all kinds of field instrument signals into the normal signals or special signals specified by users which can be accepted by the computer, DCS, PLS, etc. It is also used to isolate control equipment and operational equipment from electronics, like a relay.

The isolated barriers in our safety automation system for sale are associated equipments of explosion-proof instruments that will not affect the function of the measurement system in a normal situation. The isolation barrier is placed on one side of the security site, when the explosion-proof system fails, the intrinsic barrier can limit the energy (electric energy) which can enter the dangerous site to safe values to ensure the safety of the scene.

1. Different feature. Barrier: High reliability and precision, strong EMC performance. Isolator: Gives electrical isolation among the input & output circuits.

2. Different function. Barrier: Protect electrical signals in potentially flammable or other hazardous areas. Isolator: Adjust, isolate and transform all kinds of field instrument signals into the normal signals or special signals specified by users.

3. Main difference: Explosion proof or not.

IA means that the explosive gas mixture cannot be ignited under normal operation, one counting failure, and two counting failures. IA-level intrinsically safe electrical equipment can be used in hazardous locations in Zone 0, Zone 1, and Zone 2.

IB means that explosive gas mixtures cannot be ignited under normal operation and a counting failure. IB's intrinsically safe electrical equipment that can be used in hazardous locations in Zone 1 and Zone 2.

IC means that explosive gas mixtures cannot be ignited under normal operation. IC-level intrinsically safe electrical equipment can be used in zone 2 hazardous locations.

When the equipment is installed in an area where combustible materials exist, measures must be taken to minimize the risk of fire. Intrinsic safety barriers are considered a suitable approach, although the entire system needs to be designed accordingly. An IS will make your manufacturing safer.

No, due to the dependence on low power and low temperature, the intrinsic safety equipment cannot replace these methods in all applications. However, using intrinsically safe electrical equipment will usually greatly save installation and maintenance costs.

No, when the intrinsic safety barrier is used, the performance of power equipment is more reliable than when it is not used. The isolation barrier is designed to limit the energy stored and heat generated in the event of an internal failure.

Intrinsically safe electrical equipment is designed to limit the dangerous energy of the safe place into the dangerous place, that limit the voltage and current sent to the hazardous place—only stops dangerous levels of voltage and current, not stop signals or communication getting through.

Compare to the Nomar isolated barrier, the intrinsic isolated barrier is more advantageous.

As one of the intrinsic safety barrier manufacturers, Chenzhu has developed mature safety and automation system and can provide intrinsic isolated barriers with high reliability, high EMC performance and high safety.

1. Isolated barriers should be installed in a safe-area.

2. Electrical isolation barrier can only be connected with IS apparatus(including simple apparatus) to form an IS system.

3. Isolated barrier is not possible to link non-IS instruments form an IS system.

Generally, devices with intrinsic safety certification are slightly more expensive than non essential versions. Because obtaining and maintaining intrinsically safe certification requires additional costs. In fact, the basic design of is barrier uses zener diode to limit voltage, resistor to limit current and fuse, which are not expensive.

When electrical equipment and instruments are installed in hazardous environments, intrinsic safety barriers need to be used. The main advantages are as follows: 1. The intrinsic safety barrier helps ensure a safe working environment and protects nearby people from the risk of explosion. 2. The intrinsically safe barrier avoids the cost and volume of an explosion-proof enclosure. 3. The risk of working environment is reduced. Maintenance and diagnosis can be carried out without closing the ventilation of the production and working area, so the insurance premium may also be reduced.