The production and use of industrial alcohol, gasoline, and other flammable materials involve explosion-proof technology. Common explosion-proof technologies include explosion isolation, intrinsic safety, oil immersion, sand filling, and encapsulation. In electrical explosion protection, intrinsic safety is the most commonly used technology, requiring a key component—the intrinsically safety barriers.

Intrinsic safety technology is generally applied to instruments, and the explosion-proof purpose can be achieved through the intrinsically safety barriers. The spark generated through the safety barrier is insufficient to cause an on-site explosion. Of course, the safety barrier must be placed in a safe location, such as a control room, cabinet room, strong power area, or power supply system, to receive signals from hazardous areas (flammable and explosive on-site areas, places using intrinsically safe instruments), and it can also output signals to hazardous areas through the safety barrier.

Intrinsically safety Barriers are mainly applied in the design of intrinsically safe explosion-proof systems. The primary function of the safety barrier is to limit the hazardous energy from a safe place entering a hazardous area, as well as limit the voltage and current sent to the hazardous area. In the circuit of the safety barrier, the energy sent to the on-site intrinsically safe circuit is limited through voltage and current limiting circuits, thereby preventing dangerous energy from non-intrinsically safe circuits from intruding into intrinsically safe circuits.

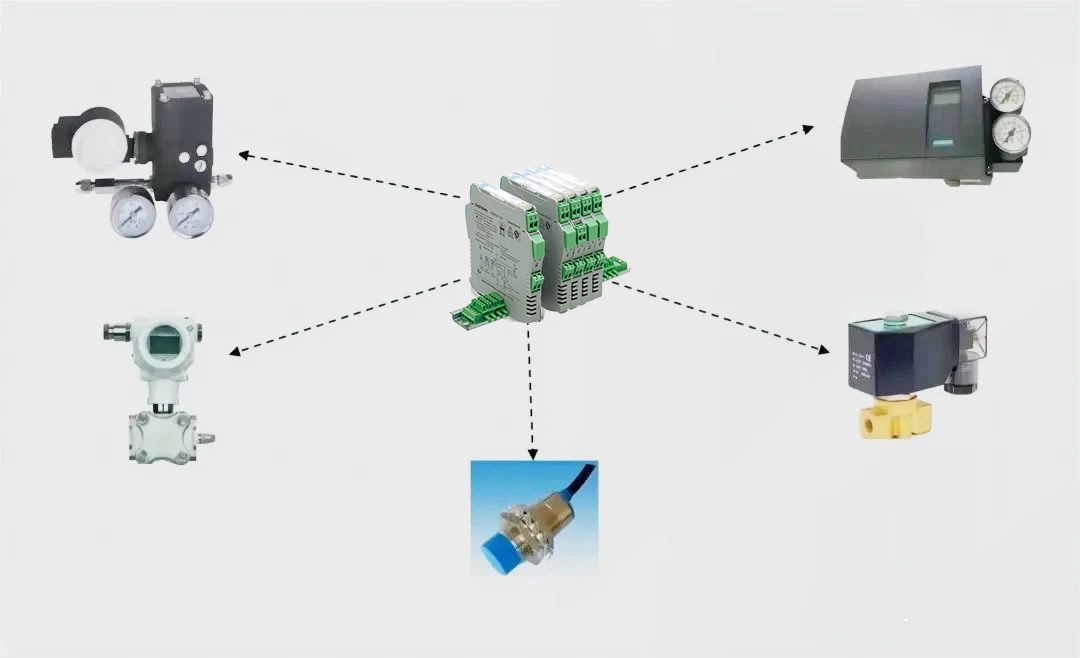

Safety barriers are widely used in the process control of industries such as petroleum, chemical, metallurgy, and power, and can form intrinsically safe explosion-proof systems with the following devices. From left to right: electrical converters, transmitters, proximity switches, solenoid valves, electrical valve positioners.

Since the safety barrier is designed as an energy-limiting interface between field devices and control room devices, it ensures that the energy delivered through it to field devices are intrinsically safety barriers, regardless of whether the control room devices are in normal operation or malfunction.

In electrical intrinsic safety explosion protection, we generally divide workplaces into explosion-proof and non-explosion-proof areas. There is energy transmission between these areas; for example, switches, buttons, and sensors in explosion-proof areas are connected via wires to PLCs placed in electrical cabinets in non-explosion-proof areas.

The role of the intrinsically safety barriers is to limit the current between explosion-proof and non-explosion-proof areas, reducing the electrical energy of signals in explosion-proof areas, thereby reducing the risk of generating electrical sparks.

Depending on the type of hazardous location and explosion-proof requirements on-site, determine the required explosion-proof grade of the intrinsically safety barriers. The explosion-proof grade of the safety barrier must not be lower than the explosion-proof marking level of the intrinsically safe on-site equipment;

Equip corresponding types of safety barriers according to the type of on-site equipment;

Determine the maximum voltage of the safety barrier based on the highest voltage that may exist or be generated by instruments in the control room;

Determine the polarity of the safety barrier based on the signal and power polarity to ground of the on-site equipment; the safety barrier must match the safety polarity and signal transmission mode of the intrinsically safe on-site instruments;

Consider the influence of resistance voltage drop at the end of the safety barrier, and determine whether the maximum short-circuit current of the safety barrier can allow the system to operate normally;

Ensure the allowed distribution parameters of the safety barrier meet the requirements.