Safety Relay is a specialized relay that has obtained corresponding safety certification under the safety standard system. In the petrochemical industry, it is a relay that meets the IEC 61508 standard and has obtained the Safety Integrity Level certification from an internationally authoritative body. It is mainly used in safety instrumented systems, connecting various parts of a safety instrumented loop (measurement instruments, logic controllers, final elements).

Especially when there might be dangerous interference signals from outside in the input/output signal (switching signals) lines of the safety instrumented system, a safety relay should be used for isolation. When the measurement instrument detects dangerous signals in the process or equipment, and an emergency shutdown command is issued by a logic controller or operator, the safety relay transmits the signal to the associated final actuator to perform safety interlock protection actions, bringing the equipment to a safe state and protecting personnel and equipment safety.

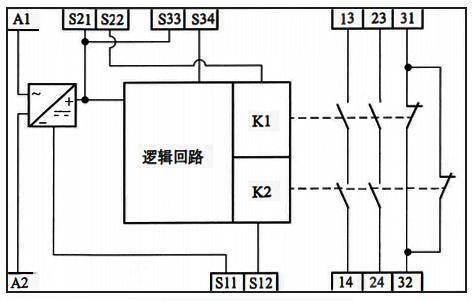

According to industry and standard system classifications, safety relays are typically divided into those used in the mechanical manufacturing industry safety relays(meeting standards EN ISO 13849, Performance LevelsPL:a~e, EN 954-1, Safety CategoriesCat:B, 1~4) and those used in the process industry safety relays(meeting standards IEC 61508, IEC 62061, Safety Integrity LevelsSIL: 1~4). Regardless of the industry they are applied to and the standards by which safety certification is obtained, the basic principles of safety relays are illustrated as shown in the diagram.

A1/A2 as the power terminals, S11/S12, S21/S22 as two sets of input channels, S33/S34 as reset terminals, 13/14, 23/24 normally open contacts NO as logic outputs, and 31/32 normally closed contacts NC as auxiliary contacts.

Redundant Configuration of the Safety Relay

As shown in the diagram, the inside of the safety relay integrates two relays to ensure reliability and meet the corresponding Safety Integrity Level.

Mechanical Interlocking Contacts of the Safety Relay

Safety relays adopt a multi-pole contact mechanical interlock design to ensure that normally open safety output contacts and auxiliary normally closed contacts cannot be closed at the same time, as shown in the diagram.

Since the contacts of the safety relay are mechanically linked together, if the normally open safety contact NO sticks, the auxiliary normally closed contact NC will open; similarly, if the auxiliary normally closed contact NC sticks, the normally open safety contact NO cannot close.

Self-Diagnostic Function of the Safety Relay

According to the design principles of safety instrumented systems for fail-safe failure, safety relays usually use normally open contacts NO as signal output contacts. Based on the mechanical interlock contact design, the auxiliary normally closed contacts NC are usually used to monitor whether the normally open contacts NO are sticking, which means that the safety relay has a self-diagnostic function.

Safety Certification

In the petrochemical industry, safety relays as a component of safety instrumented systems to achieve safety instrumented functions, are tested and certified by authoritative bodies, with relevant parameters documented.