In recent years, the number of petroleum refineries and chemical plants has been increasing. Since oil and its related products are mostly flammable and explosive, it is essential to use safe and beneficial explosion-proof methods to ensure safety. Intrinsic safety barrier, as an electrical device connecting intrinsically safe and non-intrinsically safe electrical equipment, can effectively enhance safety in the production processes of petrochemical enterprises.

The safety interface of an intrinsically safe loop, which can bi-directionally transfer electrical signals between safe zones (intrinsic safety) and hazardous zones (non-intrinsic safety) and limit energy transfer from the safe zone to the hazardous zone due to faults.

Intrinsic safety (IS) is an explosion-proof technology used in instrument systems. Safety barriers are set between control room equipment in safe areas and intrinsically safe equipment in hazardous areas to transmit signals or energy. The intrinsic safety barrier utilizes circuit current and voltage limits to restrict energy from the safe area being transferred to equipment in hazardous areas. Intrinsically safe equipment in hazardous locations can operate normally with this energy, but the energy is insufficient to ignite the explosive environment. Even if the intrinsically safe equipment itself fails, no sparks or hot surfaces that can cause ignition will be produced. Therefore, whether it is the control room equipment in the safe area or intrinsically safe equipment in the hazardous area that fails, as long as the current and voltage limiting circuit of the safety barrier works properly, the entire system will be safe and no explosion will occur.

When explosive substances, oxygen, and sources of ignition appear simultaneously, an explosion can occur. If we can eliminate any of the conditions forming an explosion, we can ensure the safety of field instrument equipment. Oxygen in the air cannot be controlled, so controlling explosive substances and sources of ignition are currently more commonly used safety principles. In the instrument industry, controlling the explosion range is also listed as a common safety principle.The intrinsic safety barrier can limit the electrical energy of field instruments, preventing them from generating sparks that can ignite or causing the instrument surface to reach ignition temperatures. Intrinsic safety technology can eliminate hidden dangers and ensure field safety.

The classification of explosive gases is shown in the table below:

Working Condition | Gas Classification | Explosive Gas | Minimum Ignition Energy |

Underground Mine | Ⅰ | Methane | 0.280 mJ |

Factory Outside Mine | ⅡA | Propane | 0.180 mJ |

ⅡB | Ethylene | 0.060 mJ | |

ⅡC | Hydrogen | 0.019 mJ |

Hazardous gas areas are divided into 3 different zones:

Zone 0: In normal conditions, places where explosive gas mixtures continuously, briefly, and frequently appear or exist for long periods.

Zone 1: In normal conditions, places where explosive gas mixtures may appear.

Zone 2: In normal conditions, places where explosive gas mixtures do not appear, and only appear briefly in rare abnormal conditions.

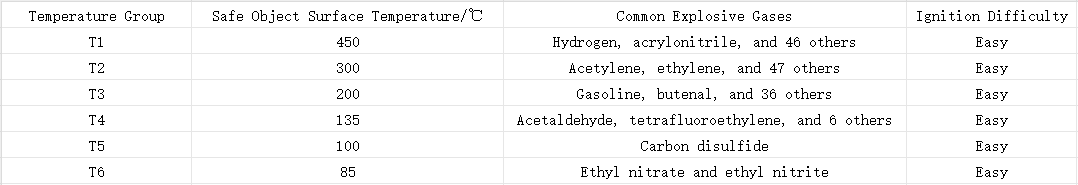

Temperature groups for explosive gases are shown in the table below: